Nissan to cut EV and hybrid car costs by 30% with powertrain overhaul

In efforts to reduce the cost of electric and hybrid vehicles by up to 30%, Nissan plans a redesign of its powertrains

The Japanese automaker recently announced its plans to streamline the assembly of parts that propel its vehicles, using the same core components across different models and modularised powertrains that include multiple components in a single unit. The strategy is set to reduce the cost of the company’s EVs and hybrid models as well as the use of expensive raw materials, reinforcing Nissan’s shift to electrification.

A new approach to powertrains

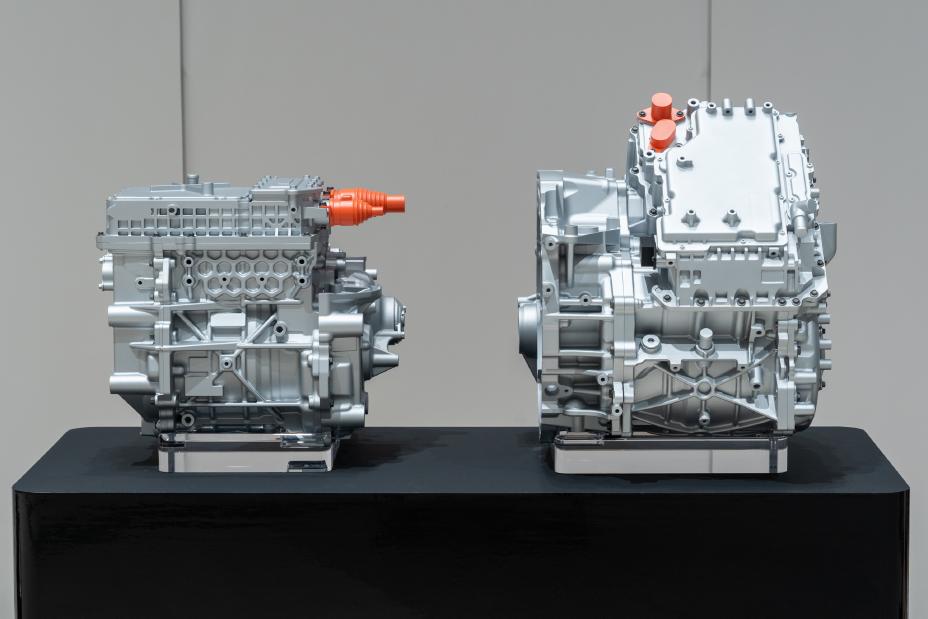

In what Nissan is calling its “X-in-1” development strategy, the company plans to apply the same powertrain components, such as electric motors and inverters, across various models as well as modularising multiple core components into single units.

Through this method, Nissan has developed a 3-in-1 powertrain prototype intended for use in its electric vehicles, which modularises the motor, inverter, and reducer. A 5-in-1 prototype, which additionally modularises the generator and increaser, is planned for incorporation into its hybrid vehicles.

According to the company, this new powertrain production approach will lower development and manufacturing costs by as much as 30% in 2026 as compared to 2019 levels and increase the competitiveness of its EV and hybrid vehicles.

In addition, by using the new production strategy, the firm says it will reduce the size and weight of each powertrain unit and thus minimise noise and vibration, improving the overall driving experience.

Senior Vice President Toshihiro Hirai, who leads powertrain & EV engineering development, said: “We make the most of our expertise and know-how from our more-than-a-decade long development and production of electrified technologies. Through our innovations in electrified powertrain development, we’ll continue to create new value for customers and deliver 100% motor-driven vehicles – EVs and e-POWER – as widely as possible.”

Reduction of rare materials

While EVs and hybrids look to offer drivers a more environmentally friendly option than petrol vehicles, their production relies heavily on rare-earth materials such as neodymium and dysprosium. The cost of the rare earths needed to produce electric vehicle batteries and other components has skyrocketed in recent years, making the reduction of these materials key to lowering EV and hybrid prices.

Compared to the auto maker’s first-generation vehicle, the Leaf, rare materials in the 2019 Nissan Note EV account for 25% of its weight. With the company’s new approach to powertrains, it looks to reduce the use of rare earth elements to 1% or less of magnet weight.

At the forefront of electrification

An electric vehicle pioneer, Nissan became the first automaker to mass-market an EV, the Nissan LEAF, in 2010. Since then, the firm has sought to continuously enhance its electrification technologies and in 2016 launched its e-POWER electrified powertrain system with a petrol engine that is not connected to the wheels, but simply charges the battery.

Having come up against stiff competition from other EV makers such as Tesla, Nissan decided to put electrification at the centre of long-term strategy and initiated a plan in 2021 to invest 2 trillion yen over a period of five years to kickstart its EV and hybrid presence. Within the plan, Nissan set out to launch 15 new EV models by fiscal year 2030 and create an electrification mix of more than 50% globally across the Nissan and INFINITI brands.

“We are proud of our long track record of innovation, and of our role in delivering the EV revolution. With our new ambition, we continue to take the lead in accelerating the natural shift to EVs by creating customer pull through an attractive proposition by driving excitement, enabling adoption and creating a cleaner world,” said Nissan COO Ashwani Gupta at the time.

For more Mobility news, click here.